Q107_ & Q108_ Kerf-In Foam Weatherstrip

With Kerf-In

- Foam kerf-in weatherstrip is constructed from soft cell foam enclosed by an embossed, tear-resistant, low-friction, UV-stable polyethylene cover

- Shape and materials conform well to irregularities in door fit and finish for a tight seal and low air infiltration

- Includes rigid PVC insert with extended flange for fast and easy kerf installation

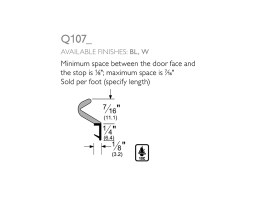

Q107_

AVAILABLE FINISHES: BL, W

AVAILABLE LENGTHS: PER 305mm

Q108_

AVAILABLE FINISHES: BL, W

AVAILABLE LENGTHS: PER 305mm

Key to Inserts

E - EPDM, Solid

M - Magnetic

N - Neoprene or EPDM*

NB - Nylon Brush

P - Pile

PK - PemkoPrene®**

Q - Kerf-in Foam

R - Sponge Neoprene or EPDM*

S - SiliconSeal or Sponge Silicone (see individual part)

SB - Soft Brush

T - ThermoSeal™

TF - Triple Foam

V - Eco-V™

*N: As we “Green,” inserts “N” may be either Neoprene or EPDM.

*R: As we “Green,” inserts “R” may be either Sponge Neoprene or Sponge EPDM.

Over time, these inserts will move to EPDM material.

**PK: In order to best control our customers’ costs some PK (Santoprene™) products may be a silicon based elastomeric material with comparable performance.

Finishes

BL (Black) W (White)

![]()

Environmental Sealing & Seal Selection

Weather sealing will only apply generally to external doors where the degree of sealing required will be determined by the doorset location and the extent to which it is exposed to external climatic conditions. Doorsets located in protected external locations will generally require a lower level of sealing than exposed external doors that are subjected to high wind pressures.

Similar considerations may apply to internal locations where there is a need to control room pressures. e.g. laboratories or hospitals. The requirement for effective sealing applies to all buildings whether they are industrial, commercial, public or residential, indeed, any type of building where it is necessary to reduce the transfer of noise, air, smoke, odours and vermin that might otherwise find a route through the operating gaps around door leaves and windows.

The purpose of the door will have an influence on the choice of seals, e.g. sealing of external doors for (say) plant rooms that are only used by able bodied maintenance staff may be considered differently to doors in locations that are to be used by the general public and in particular disabled users. Pemko seals generally fall into a low operating force category but it may be necessary to use a combination of seals to meet performance requirements for some locations.

For exposed locations for use by the general public we recommend that consideration is given to the construction of performance lobbies. This permits the use of low force sealing arrangements that have little influence on the operation of the doors with the added advantage that some level of sealing is maintained where one of the lobby doors is open while the other remains closed.